Magnetic field

Magnetic field influences inversely the sputtering voltage. In other words, when the magnetic field on the surface of the sputtering target increases, the operating voltage of magnetron sputtering will decrease. It happens because the sputter-etched surface of the target gets closer to the strong magnetic field of the permanent magnet behind the target. To be noted, when the magnetic field strength increases above 0.1T, its effect on the sputtering voltage is no longer obvious.

In order to reduce the influence of this factor, the thickness of the sputtered material is not arbitrary, but limited. In general, thicker non-magnetic targets can be used in stronger magnetic fields.

Material Type

Different target materials also affect the sputtering voltage. Here are examples of ITO, copper, aluminum, titanium, manganese, and chromium target.

| Sputtering Target | Sputtering Voltage |

| Indium Tin Oxide (ITO) | ≈200V |

| Copper (Cu) Aluminum (Al) Titanium (Ti) |

400~600V |

| Manganese (Mn) Chromium (Cr) |

>700V |

Gas Pressure

Working gas pressure

Under the condition that various parameters (such as environmental conditions, power control panel parameters, etc.) remain unchanged, the increase of the working gas pressure will reduce the magnetic sputtering voltage.

Reactive gas pressure

On contrary, under the determined environment and constant power source, the increase of reactive gas pressure will result in the increase of magnetic sputtering voltage.

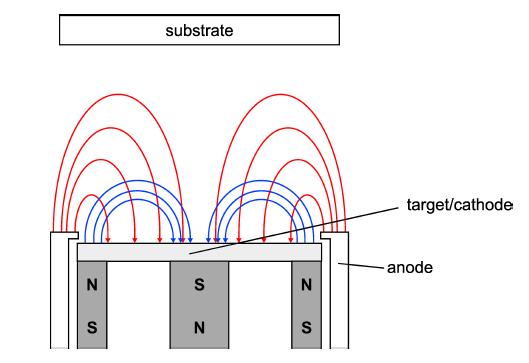

Distance Between Cathode & Anode

The distance between the cathode and anode in vacuum gas discharge can have a certain effect on the sputtering voltage. If the distance is too large, the internal resistance of the equivalent gas discharge is mainly determined by the plasma equivalent internal resistance. Conversely, if the distance is too small, the internal resistance of the plasma discharge will be small.

When the magnetron target ignited and enters the normal sputtering, if the distance between the cathode and anode is too small, although the sputtering current has reached the process setting value, the target sputtering voltage is still low.

Please visit https://www.sputtertargets.net/ for more information.