Copper sputtering targets, as part of vacuum coating materials, are widely applied in tool coating, optics coating, solar coating, and etc. Copper targets can be put together with metallic copper because they are essentially the same–composed by Cu atoms.

Development of Copper

Copper is one of the earliest metals discovered by mankind and the first metal that humans began to use. Copper beads made of natural copper excavated by archaeologists in northern Iraq are supposed to have been more than 10,000 years old. Methods for refining copper from its ores were discovered around 5000BC and a 1000 or so years later it was being used in pottery in North Africa.

In modern industry, copper was widely used in the power and electronics industries. By the 1960s, copper used in these two industries accounted for 28%. By 1997, these two industries were still the main areas of copper consumption, accounting for Than 25%. Later, copper was widely used in electrical, light industry, machinery manufacturing, construction industry, transportation, and other fields. As far as America is concerned, copper is second only to aluminum in the consumption of non-ferrous materials. Copper has excellent performance and is easy to recycle and recycle. At present, there are already relatively complete recycled copper recycling systems in developed countries. For example, the output of recycled copper in the United States accounts for 60% of the total output, and Germany accounts for 80%.

Copper Sputtering Target Property

Copper is a chemical metal element with the symbol Cu. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkish-orange color. Copper is used as a conductor of heat and electricity, as a building material, and as a constituent of various metal alloys, such as sterling silver used in jewelry, cupronickel used to make marine hardware and coins, and constantan used in strain gauges and thermocouples for temperature measurement.

| Material Type | Copper |

| Symbol | Cu |

| Color/Appearance | Copper, Metallic |

| Melting Point | 1,083 ℃ |

| Density | 8.96 g/cm3 |

| Sputter | DC |

| Type of Bond | Indium, Elastomer |

| Comments | Adhesion poor. Use interlayer (Cr). Evaporates using any source material. |

From Metal Copper to Copper Sputter Target

The copper sputtering target is a kind of copper product made of the metal copper, and it is used in the sputter coating to produce copper thin film. Simply speaking, there are two methods to make copper sputtering target from metal copper.

Casting: melt the raw material of a certain distribution ratio, pour the alloy solution into a mold to form an ingot, and finally machine it to become a sputtering target. The method is smelted and cast in a vacuum.

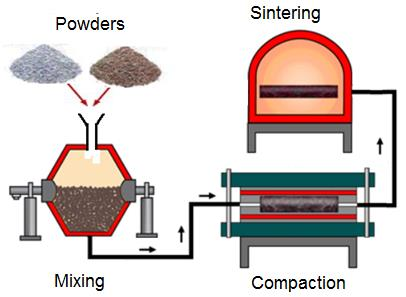

Powder metallurgy: melt the raw material of a certain distribution ratio, cast it into an ingot and then pulverize it, isostatically press the powder, and then sintering it at a high temperature to finally form a target.

Basic Requirement of Copper SputterTarget

In general, when measuring whether the sputtering target meets the primary requirements, one would consider the following indicators:

Purity: Purity has a great influence on the performance of the film produced by sputter coating. Taking copper target as an example, the higher the purity is, the better the corrosion resistance and electrical and optical properties of the sputtered film are.

Impurity content: The impurities in the solid of the target material and the oxygen and water vapor in the stoma are the main pollution sources of the deposition film. Targets for different applications have different requirements of their impurity contents.

Density: The density of the target not only affects the sputtering rate but also affects the electrical and optical properties of the film. Thus, in order to reduce pores in the solids of the target and improve the properties of the sputtered film, the target is usually required to have a higher density.

Grain size and grain size distribution: For the same target, the sputtering rate of the fine-grained target is faster than that of the coarse-grained target; and the thickness of the target sputter-deposited film with a smaller difference in grain size (distributed uniformly) is more uniform.

Information provided by SAM Sputter Targets.